Vixtera received the US patent for the fault detection in a system of connected devices

Blog

We live in a fantastic time when technology practically rules the world. Now devices are no longer a luxury, but an everyday household item. Only 5-10 years ago, people could not think that wireless communications would be so popular and would become a key element not only in everyday life but also in the leading technology in production.

Production owners have faced problems of increased demand, growing customer expectations, as well as the establishment of global supplies recently. All this encourages the owners of large enterprises to generate new ideas and ways to maintain a place in the manufacturers’ market.

Many companies turn to IoT trying to increase the efficiency and safety of production, as well as not to lose out, and at the same time reduce the cost of maintenance of the enterprise. This technology can give a lot to the production. In this article, we will plunge into the world of IoT and understand the benefits of implementing this technology into production.

Page Contents

Like any other enterprise, IoT uses sensors and detectors to track up-to-date and vital information. In addition to collecting information, IoT technology keeps it in cloud storage to subsequently use these data to analyze the effectiveness of the enterprise, as well as the subsequent improvement of production processes.

The industrial revolution is the transition from manual work to machine labor. The same thing is happening with production. This business is experiencing a fourth revolution now. And if previously there was exclusively manual labor, that is, now everything is somewhat different. At the moment, most industries are partially automated but still need a human presence. The essence of the fourth revolution is to completely eliminate the human factor and replace it with more precise mechanisms. Various applications, sensors, detectors that use technologies such as AI and IoT are more effective for production work.

Numerous studies show that most enterprises suffer from low productivity. This problem is one of the most pressing in business. There are two possible solutions to increase performance and production efficiency: managerial and economical. Management tools are aimed at increasing staff involvement, and economic instruments are aimed at optimizing processes, modernizing production, and reducing the time spent on manufacturing products. In our case, we are interested in the second option.

Based on the existing problems, many manufacturers have relied on new IoT technology. They have already actively implemented its devices to reduce maintenance costs and increase labor productivity.

The introduction of modern technology is the best investment in the future of production. What changes can occur with the implementation of IoT we will discuss below.

Built-in location sensors in products and cars will help storekeepers to prevent a shortage of products in the warehouse, avoid unnecessary loading, and monitor the condition of the goods remotely. From a consumer point of view, these same sensors will help customers track the product from the beginning to the end of the manufacturing process.

The presence of sensors can solve the problem of planning and scheduling since each product and machine can exchange data so it will be possible to achieve faster delivery.

Constant monitoring would help reduce the human factor, and this will undoubtedly have a positive impact on productivity. This is because it is not profitable for the company to spend valuable time on errors and inaccuracies that people can often make by tracking and documenting the data of all machines manually. At the same time, sensors can simultaneously measure pressure, water level, electricity, and temperature, enhancing production quality control.

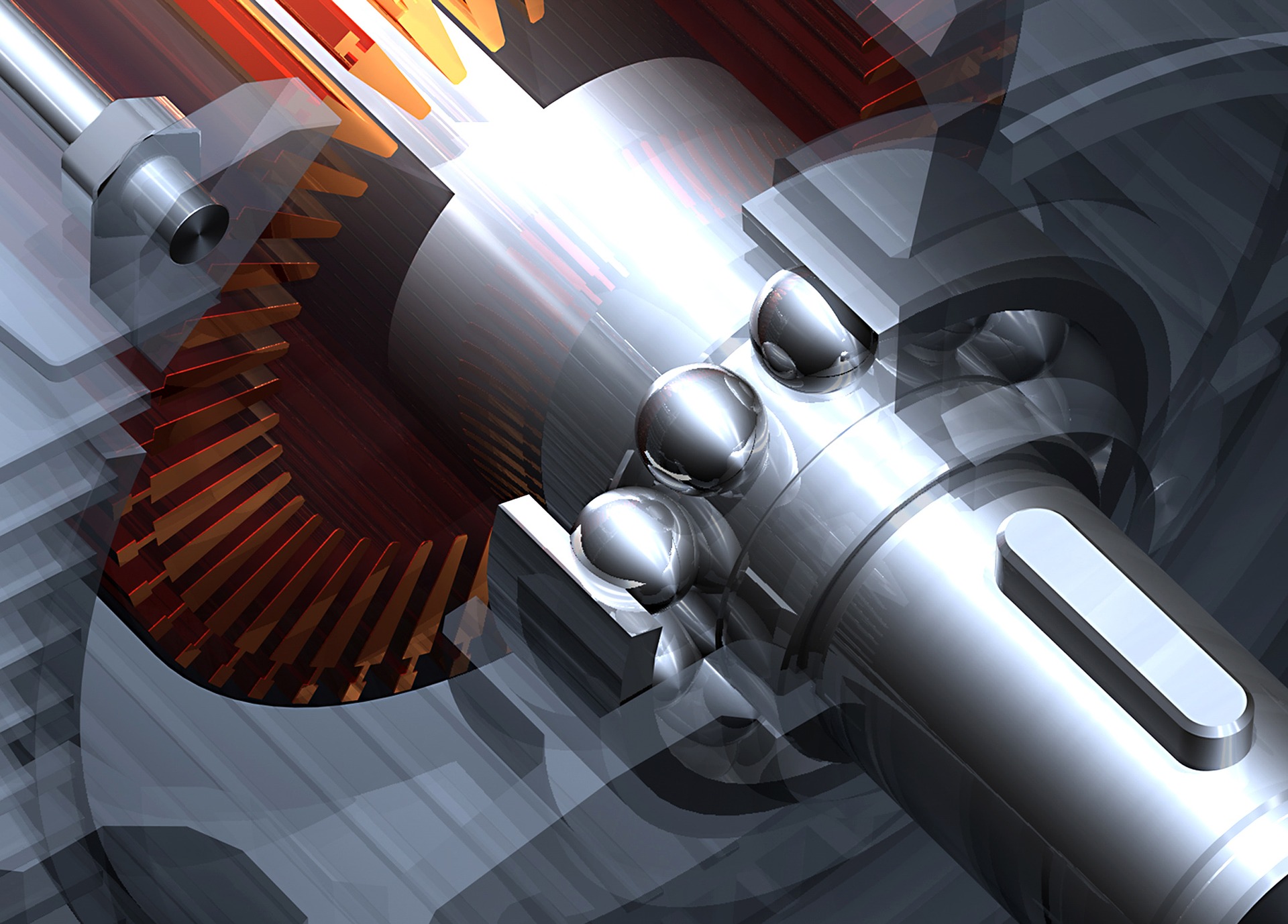

When the majority of machines in production have built-in sensors, this favorably affects most operations of the industry. In the event of a system or machine failure, the sensors respond quickly, detecting the place of failure and automatically notify the manufacturer about the problem.

Vixtera invented a complete solution to reduce the costs of a laborious and time-consuming task of installing devices and modeling AI. ViEdge is a unique algorithm that can analyze the root causes of production failures. Moreover, the algorithm uses the cause of failure as a label to generate training data for NN for the future prevention of such problems.

This solution helps to eliminate the human factor, which very often can make mistakes both in device configuration and in AI modeling.

ViEdge is a reliable source for predictive analysis, as well as an accurate and reliable data generator for applications and various services.

Since the introduction of IoT in production has occurred recently, do not wait for the full automation of processes. People need some time to become acquainted with innovations and technologies. It follows that enterprises have to strike a balance between humans and automated systems. For example, it is better for a person to give work to a robot if a place is potentially unsafe, and it is better to give work to a person, for example, at the sawmill, after ensuring reliable protection.

Human security control begins even before the start of the workflow. If an employee is highly qualified and experienced enough, they are assigned to a more dangerous job, where needed more serious protection methods. Also, some enterprises give smart bracelets to their employees, which control pressure, pulse, number of steps, and quality of sleep. All these things are of interest to the authorities because the more a person goes in for sports and moves, the more effective he is; the quality of sleep also affects how well and focuses the employee will do the work.

Cameras and sensors are optional devices that monitor safety. They register employees for the presence of a helmet, gloves, whether someone went beyond the restrictive line, as well as the number of working hours.